Space

Space

Empowering Space Exploration with Precision and Innovation

At Prisma Electronics, we are at the forefront of space activities, specializing in the manufacturing and research & development of electronics projects. As trusted subcontractors for Space Agencies, Satellite Manufacturers, and Space Products Developers, we prioritize quality, cost-effectiveness, and timely delivery to ensure we are your reliable partner for Electronic Manufacturing Services (EMS).

Unmatched Quality and Reliability

Our commitment to excellence is underscored by stringent supervision from our PA/QA Engineers at every production phase, ensuring the utmost reliability of our deliverables. With 20 years of experience in meeting Critical Project Management requirements, Prisma Electronics boasts the infrastructure and personnel qualified to ESA standards, ready to tackle demanding projects with complex electronic needs.

Award-Winning Excellence

Our dedication to quality has earned us the prestigious “Gold Industry Award” from CERN, a testament to the exceptional standard of our work. This accolade reflects our position as leaders in the field, consistently delivering projects that meet and exceed expectations.

Comprehensive Space Electronics Services:

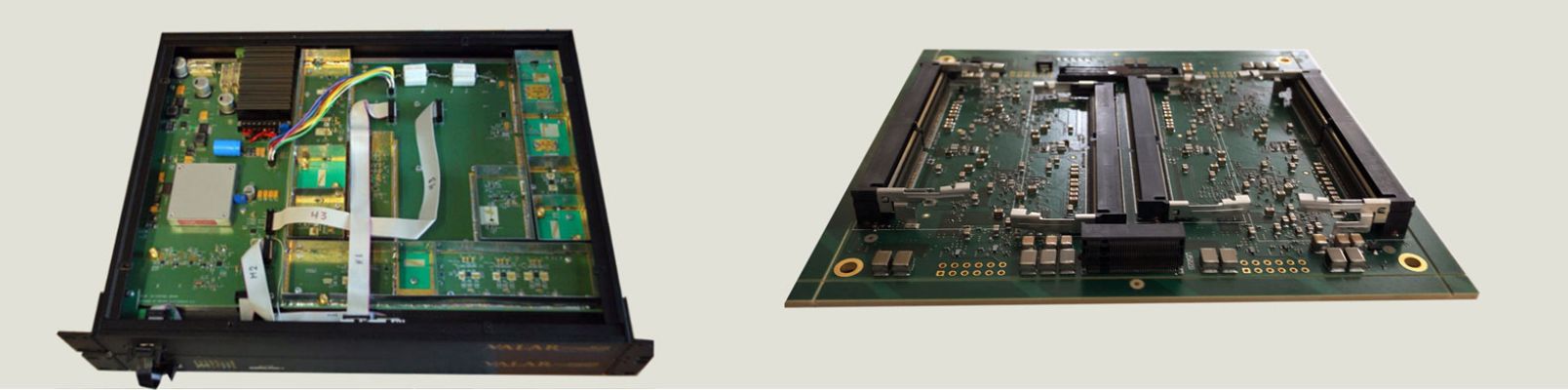

PCB Design & Assembly: Crafting precision-engineered printed circuit boards to power the next generation of space exploration.

Cables & Harnessing Design & Assembly: Ensuring reliable connections and performance in the harsh environment of space.

Device/System MAIT: Offering full-spectrum Manufacture, Assembly, Integration, and Testing services for devices and systems designed for the final frontier.

On-site Support Services: Providing expert assistance and support right where you need it.

Test Aid Design & Manufacturing: Creating devices that ensure your equipment is space-ready.

Specialized Services for Space Readiness:

Isolation and Continuity Test: Verifying the integrity and performance of electrical systems.

Bake-out Process: Preparing components for space by eliminating contaminants.

Burn-in Test: Ensuring long-term reliability through rigorous stress testing.

At Prisma Electronics, we don’t just participate in space exploration; we enable missions that reach beyond the stars. With a portfolio that demonstrates our capacity for excellence and innovation, we invite you to partner with us for your next project in the expanding universe of space technology.

The modern production lines support Space projects implementation (Solar Orbiter, Sentinel-6) for the complete MAIT (Manufacturing, Assembly, Integration & Test) for:

- Cables & Harnessing

- Test Bench Manufacture

- PCB Assembly

- Breakout Boxes Design & Manufacture

- TVac Cables

- Payload Jumper Cables

- SpaceWire Testers

Today, the Company successfully delivers a wide range of made-to-order products for Space Missions.

Some key production procedures include:

- Market Survey for the Procurement of Materials. The Company retains an updated database with approved suppliers, while constantly evaluating them and seeking for new ones.

- Throughout internal inspection of the materials during procurement.

- Utilization of calibrated assembling and measuring tools during manufacturing.

- Capability to perform a mechanical tensile test on crimped and soldered joints, according to customer requirements.

- Generation of Isolation & Continuity Test Reports for Cables production.

The strict ISO procedures of the Company follow the ESA ECSS standards for verification of components, prior acceptance, for Space Hardware assembly. This way, we can guarantee the quality and reliability of the deliverable.

Prisma Electronics can support the following:

- Procurement of components according to ECSS standards (COTS, HI-REL, Rad Hard, PCB, mechanical parts etc)

- Soldering of various component types for Prototype & Breadboard:

- Soldering of through-hole components

- Soldering of SMD components

- Fine pitch soldering

- Soldering of wired components

- Thermal pre-soldering processes

- Degolding and pretinning component lead

- Cleaning of parts and subassemblies

- Conformal Coating

- Mechanical and electrical integration

Dedicated Operators and Inspectors are certified in PCB assembly procedures, according to the following ESA Standards:

- • ECSS – Q – ST – 70 – 08C, “The manual soldering of high-reliability electrical connections”

- • ECSS – Q – ST – 70 – 28C, “Repair and modification of printed circuits board assemblies for Space use”

- • ECSS – Q – ST – 70 – 38C, “High-reliability soldering for surface mount and mixed technology”

The PCB MAIT (Manufacturing, Assembly, Integration and Test) activities for Space Projects (including commissioning) are carried out by certified and conducted operators in a Clean Room Class 10.000, ISO-7 atmosphere. The Clean Room holds the appropriate certifications for High level Cleanness, which are renewed periodically by external partner.

It is equipped with:- 3 soldering and 1 inspection workstation

- Degolding and pretinning solder baths

- Comprehensive rework soldering station

- Vacuum drying oven

- Fume hood

- Microscopes

- ESD protection

Company employs dedicated technicians and engineers, which operate according to the highest quality standards. Operators and inspectors are trained and certified every two years by a certified-by-ESA institution in the following standards:

ESA ECSS Standards- o ECSS-Q-ST-70-08 : Manual Soldering of High-Reliability Electrical Connections

- o ECSS-Q-ST-70-38 : High Reliability Soldering of SMD components

- o ECSS-Q-ST-70-28 : Repair and Modification of PCB Assemblies for space use

Prisma Electronics can provide Project Management Services and Support. Well-trained engineers guarantee the following of the proper procedures during the entire project.

Company’s internal procedures set the general guidelines.

Specific Work instructions are created for every Space project, according to the requirements of the Customer and the applicable standards.

Serial Number tracking system follows the components from the in-factory acceptance, until the delivery of the finalized product. Complete documentation (EEP, EIDP, etc.) accompanies each deliverable.

In case of Critical components and Long Lead Items, specific procedures are defined and followed.